Topaz FX – Fighting Heat Stress

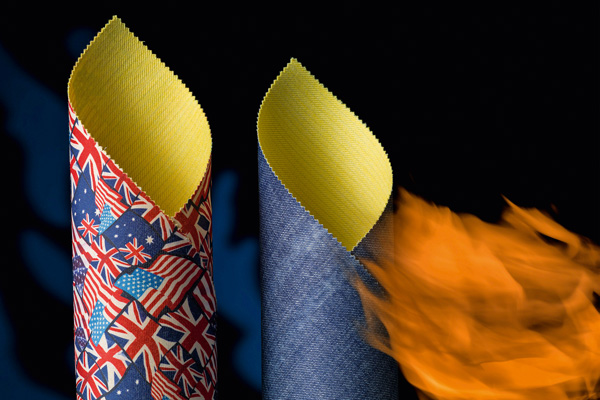

The patented „low heat stress“ technology Topaz FX from Trans-Textil makes flame resistant high performance textiles even lighter and more breathable. Topaz FX thus reduces the risk of heat stress and enables increased physiological performance in use.

The patented „low heat stress“ technology Topaz FX from Trans-Textil makes flame resistant high performance textiles even lighter and more breathable. Topaz FX thus reduces the risk of heat stress and enables increased physiological performance in use.

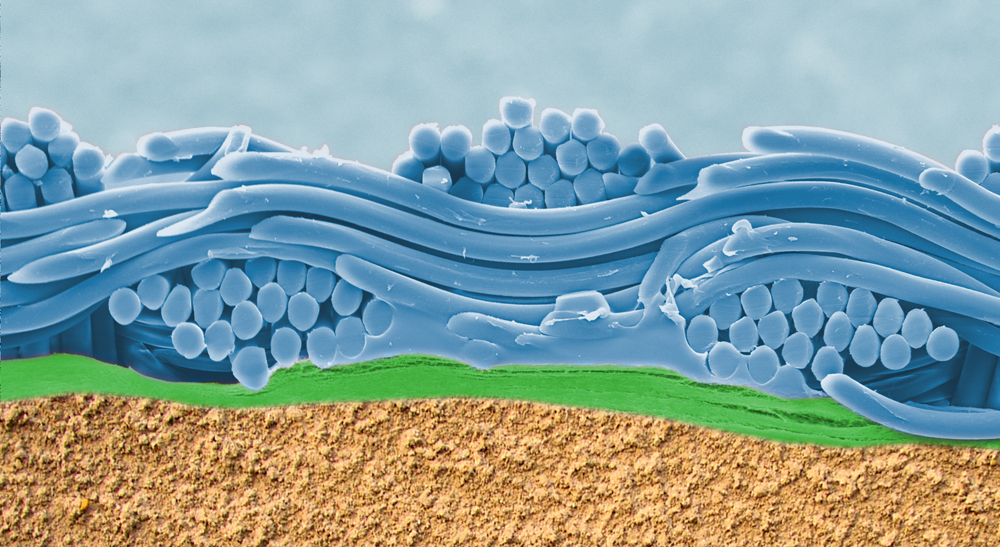

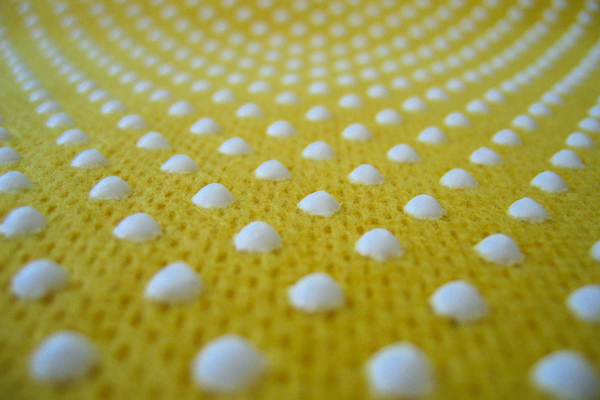

The permanent 3D structure of Topaz FX®, as an active moisturedynamic grid, ensures optimized moisture management, the rapid transport of sweat away from the body and fast drying.

The Topaz FX technology is available as 2- and 3-layer laminate with waterproof, breathable high-performance membrane systems from Trans-Textil, as well as lining fabric, base layer and protective hoods offering up to 60% less weight. All components are certified accoding to STANDARD 100 by OEKO-TEX®.

Editorial contribution in “Trendbook Technical Textiles” »

The patented „low heat stress“ technology Topaz FX from Trans-Textil makes flame resistant high performance textiles even lighter and more breathable. Topaz FX thus reduces the risk of heat stress and enables increased physiological performance in use.

The patented „low heat stress“ technology Topaz FX from Trans-Textil makes flame resistant high performance textiles even lighter and more breathable. Topaz FX thus reduces the risk of heat stress and enables increased physiological performance in use.