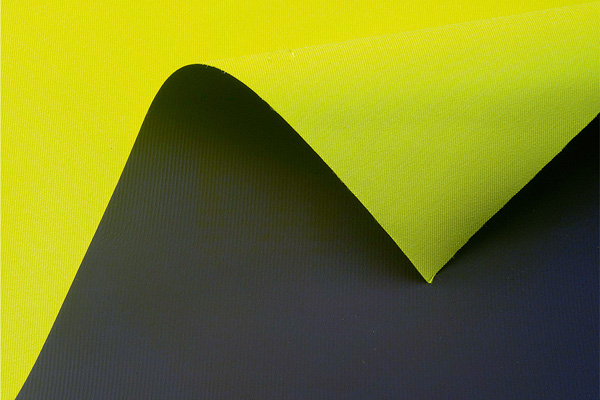

Coatings for additional synergy effects

The cutting-edge processes deployed by Trans-Textil in the coating of fabrics, membranes or finished laminates yield new synergistic effects. Our Applications Technology Department develops and implements new solutions according to customers’ requirements by varying different process parameters. These range from whole area or intermittent application and use of rotary screens or doctor blades to application in foam or paste form and deployment first and foremost of aqueous coatings as well as solvent-based ones.