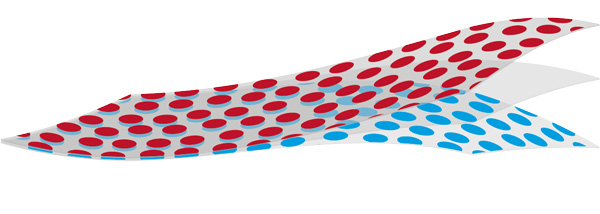

Lamination: High-tech, dot for dot.

Trans-Textil produces two-ply, three-ply and multi-ply textile laminate systems, whereby modern irreversible hot-melt adhesives, precise electronic dot bonding control and extensive know-how in the field of membranes ensure optimum results.

We set standards in our continual efforts to take lamination technology even further.