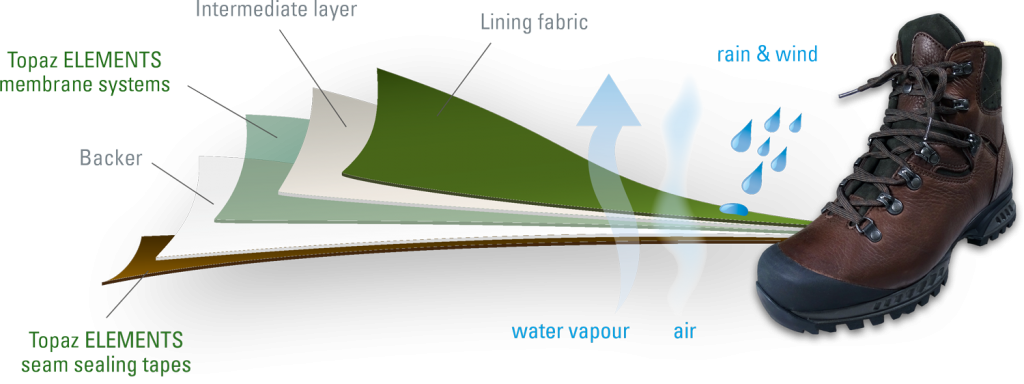

Hightec laminates for functional shoe components

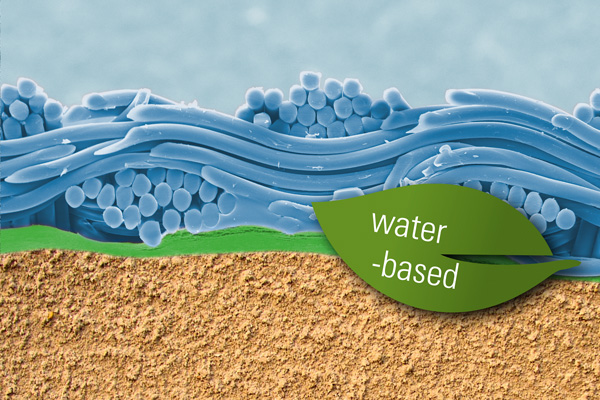

Trans-Textil’s broad portfolio of membrane laminates and products with further finishing treatments enable the ideal interplay of components and technologies in footwear products. Outerfabrics, breathable liquid barriers and textile linings – all geared to the application in question – ensure best possible protection and well-being for work and safety shoes according to DIN EN ISO 20344 as well as quality women’s, men’s and children’s shoes for outdoor, sports and leisure use. Trans-Textil’s innovative lamination and coating processes and its proprietary transfer process broaden the options for individualised product design and also guarantees superb comfort and durability.

This enables Trans-Textil to offer a unique degree of freedom in the production of textile laminates for membrane shoes offering the optimum in price, technical attributes and additional functions.