Topaz COMPANION® 3D – Fiber-based 3D membrane systems

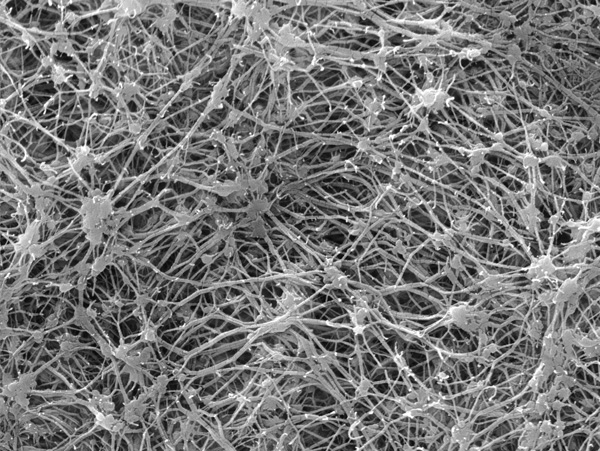

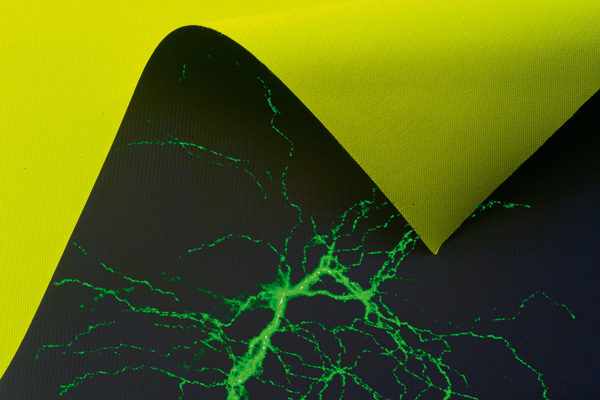

The basis for the outstanding properties of the Topaz Companion® membranes is their fiber-based 3D structure made of specially developed high-tech polyurethane. The microporous structure in the nano range combines technical performance and comfort with high ecological standards. The new membrane systems are highly breathable, ultra-light, elastic and waterproof, even after several washing cycles. The certificate according to STANDARD 100 by OEKO-TEX® confirms the human-ecological harmlessness. Topaz COMPANION® 3D systems thus become the basis for ultra-light laminate composites with high wearing comfort and reliable weather protection for daily active use in outdoor, sport, fashion and leisure.

Request information »