Wind energy

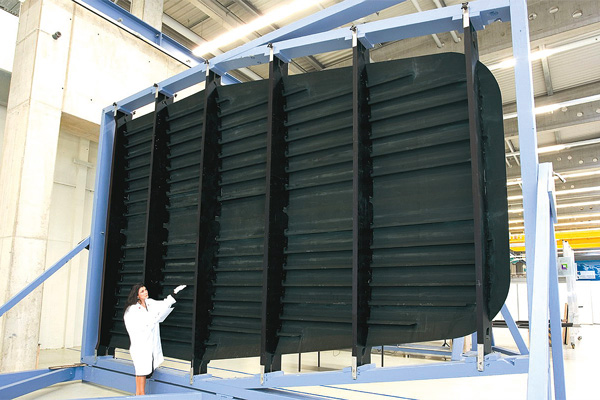

The blades of modern wind turbines are exposed to enormous loads. The high process reliability and component quality guaranteed by the Vacuum assisted process VAP® has convinced numerous leading manufacturers worldwide to opt for this solution. In today´s growing market, there is a huge demand for processes with a high degree of standardisation and special solutions that enable continuous enhancements.

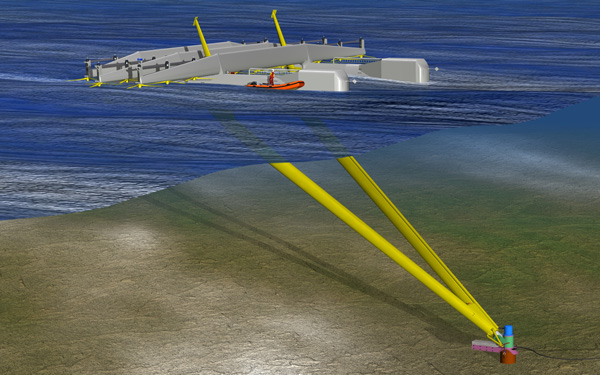

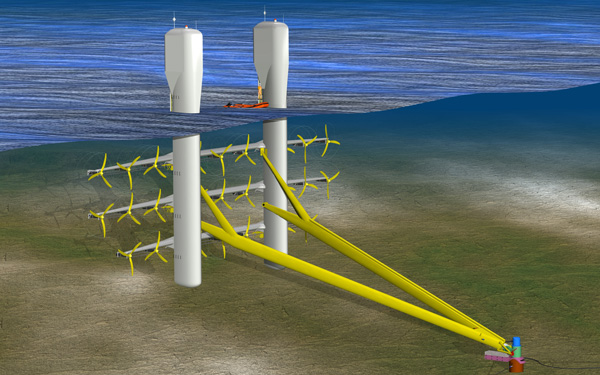

The VAP® membrane systems made by Trans-Textil have been used in the production of wind turbine rotor blades for many years. We conduct research and development in this high-tech field, thus investing in cutting-edge technologies as well as alternative power generation methods.