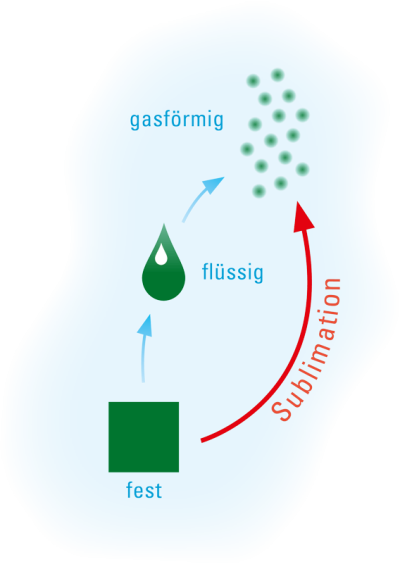

Thermal sublimation technology

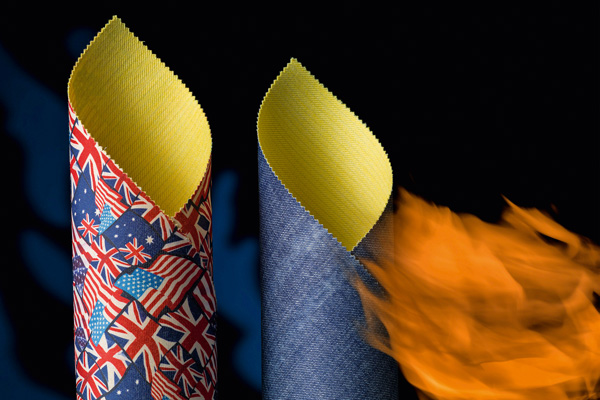

During the transfer printing process, molecules of harmless disperse dyes pass directly from a solid state into gaseous components, thus skipping the liquid state. The application of pressure and heat enables them to penetrate deep into the interior of the fibres, where they become fixed. This results in printed images with a particularly high degree of colour brilliance and optimum properties in terms of:

- colourfastness, including lightfastness and washfastness,

- abrasion resistance,

- high-temperature durability and wash resistance, and

- full retention of protective effect, function, and comfort.

The process is suitable for products made from polyester fibres and also for blends incorporating natural fibres such as cotton, viscose, linen, and wool, enabling the creation of a unique look and feel.

Request information »